Polycrystalline diamond is extremely hard and is produced by sintering together selected diamond particles with a bonding matrix under high pressure and temperatures. As a result of its extreme hardness and toughness, PCD is extremely wear-resistant and has high thermal conductivity. The combination of the excellent hardness and wear properties of the diamond with the strength properties of the carbide makes PCD a cutting tool material that permits metal cutting performance up to the very limits of today's the machine tools and metal cutting systems.

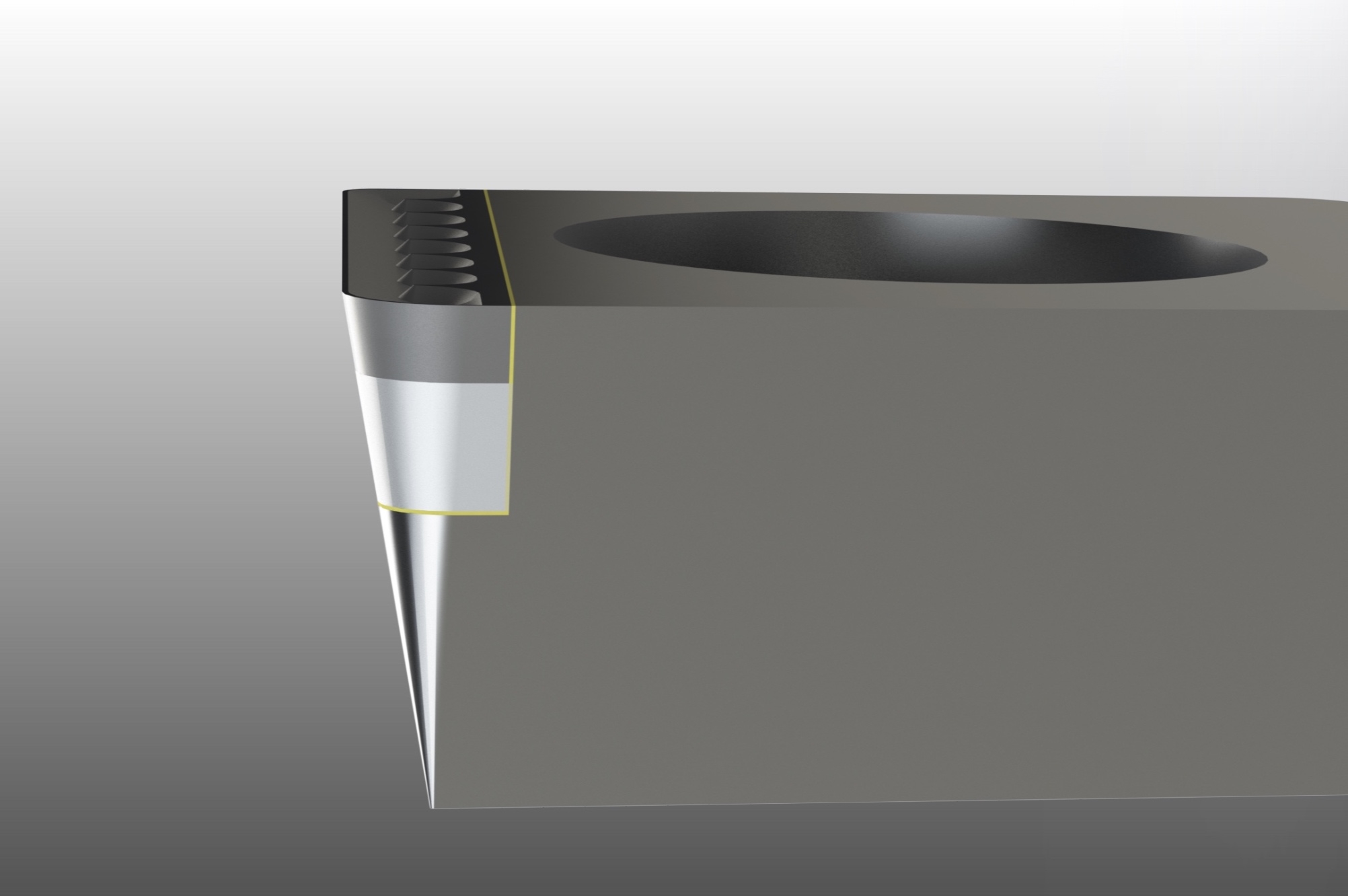

PCD with Laser-Chip-Breaker

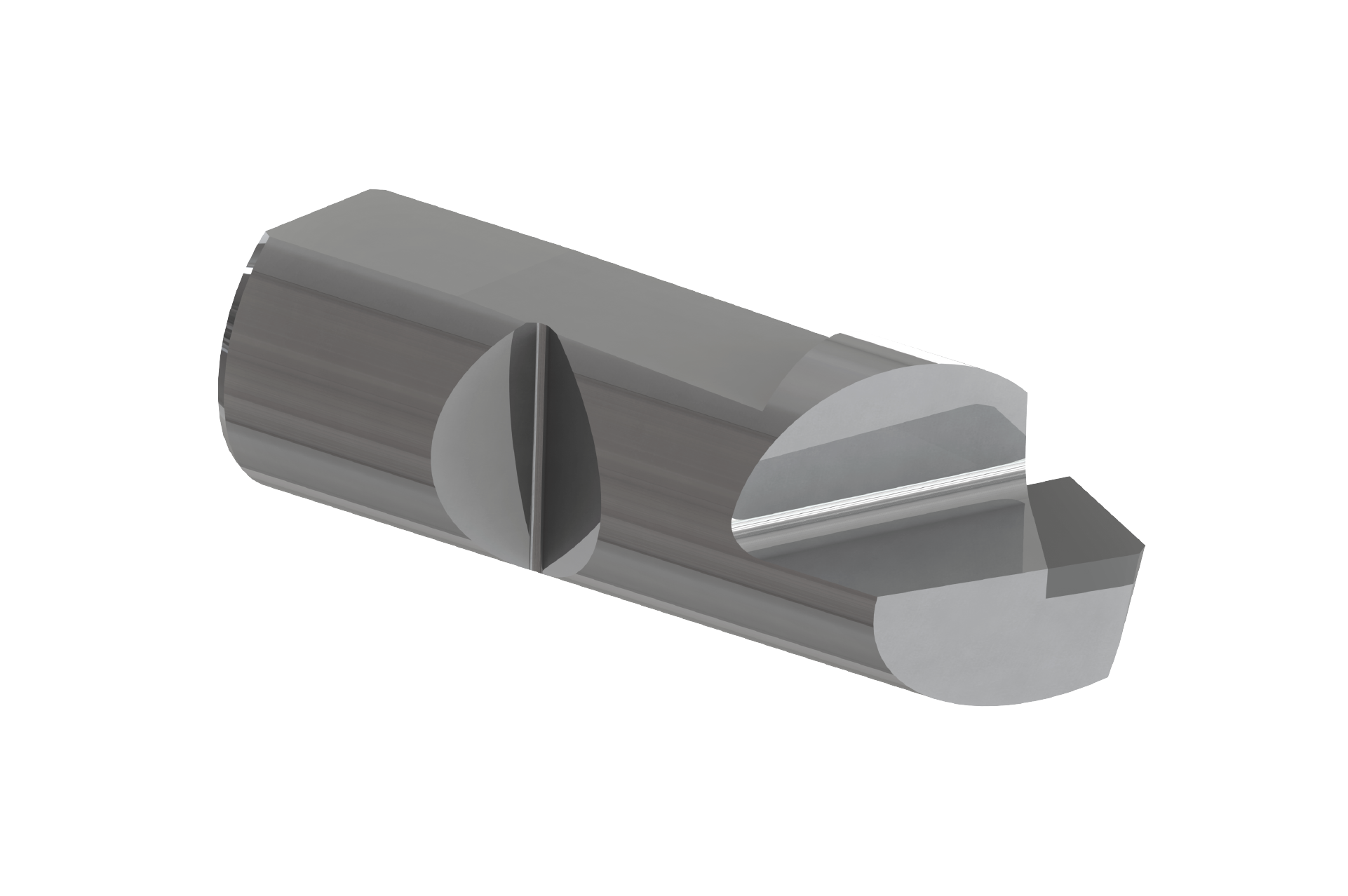

PCD - Milling Cutter Insert

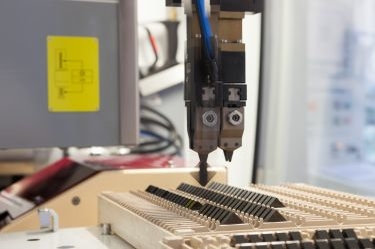

Automated Production

We use a wide range of PCD types from different manufacturers to enable you to best perform your tasks.

Advantages in overview:

- Ultra hard cutting material - great suitability for aluminum

- Good heat dissipation through PCD material and the additional better vacuum soldering

- Significantly better connection between HM carrier and PCD segment due to high-vacuum soldering

- Upon request, laser-inserted chipbreaker, prevent controlled flow chips

- Depending on the application with edge finish or sharp edge