Cubic boron nitride is the second-hardest known material after diamond, and as such, is ideal for cutting tools that wears far more slowly than those with other cutting tool materials. We therefore achieve a very high degree of shape and dimensional accuracy and can machine hard materials such as steel more reliably.

CBN Solid - Shapes

CBN - Insert

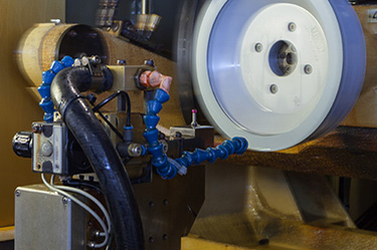

CNC - Production

The good thermal conductivity means that the high grinding temperatures do not affect CBN, and the resulting metal cutting heat is not a problem either.

Advantages in overview:

- Very wear-resistant cutting material

- Good heat dissipation through CBN material and the additional better cause vacuum soldering

- Significantly better connection between HM carrier and CBN segment due to high-vacuum soldering

- Upon request, laser-inserted chipbreaker, prevent controlled flow chips

- Longer tool life thanks to a cutting edge finish

- Individual coatings increase the tool life again

- Inserted clamping cups ensure a tight fit in the holders with clamps