CVD-diamond exceeds PCD in terms of mechanical and thermical properties by far. Especially in high wear applications it shows clear advantages. CVD consists of pure diamond without binder which is extracted from gas phase by a special C(hemical) V(apour) D(eposition) process. Certainly due to the more complex manufacturing processes it has to be evaluated if there is an economical advantage for the user at the end.

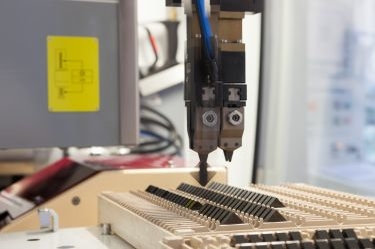

Automated Production

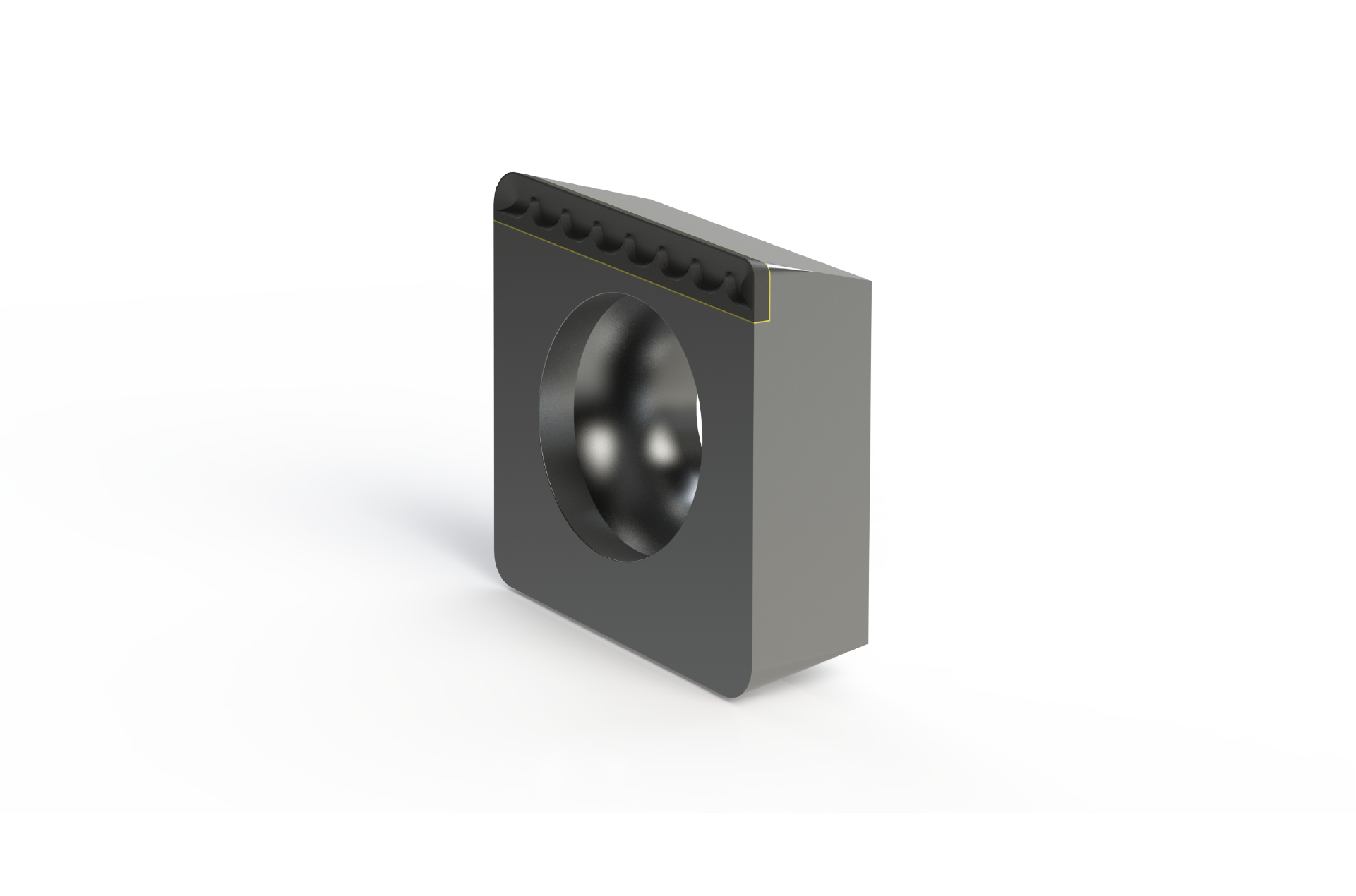

CVD - Insert

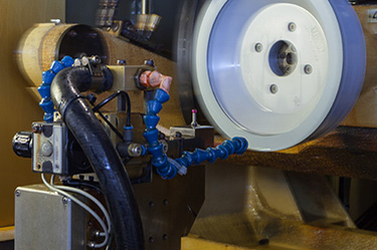

CNC - Production

CVD has to be brazed in high-vacuum which is be done inhouse with state-of-the-art equipment. Additionally in many cases a lasered chip-form geometry is used to optimize the machining process all in one. We use different grades from different OEMs and are therefore able to take the right choice for your application.

Advantages in overview:

- Hardest known artificial cutting material

- Pure diamond material without binder matrix

- thus highest resistance to abrasive substances

- thereby best heat dissipation v.a. also by the conclusive vacuum soldering

- Upon request laser-cut chipbreaker